I bought a paper cup making machine from Osaka International two year ago and it is really long-lasting in nature. I would like to recommend Osaka International to those who want to buy Paper Cup-making Machines at wallet friendly prices.

Manufacturers , Supplier, Exporter, Importer, Service Provider, Wholesaler

2005

Rs. 5 - 25 Crore

11-50

Proprietorship

06AAKPD5048D2Z1

India’s leading Agricultural Machine Manufacturers in Haryana

We, Osaka International, work presently in the sphere of manufacturing. We are a renowned Agricultural Machine Manufacturers in Haryana. Our strength lies in the latest and advanced machines that assist our clients to enhance the production. As part of our commitment we are always improving our products to meet the requirements of the Indian farmers.

Our products are well-known in the industry for their outstanding performance and features. We consistently provide our clients with the highest quality standards and within a certain time limit because we are a client-focused organisation.

We back your Business with our Machines

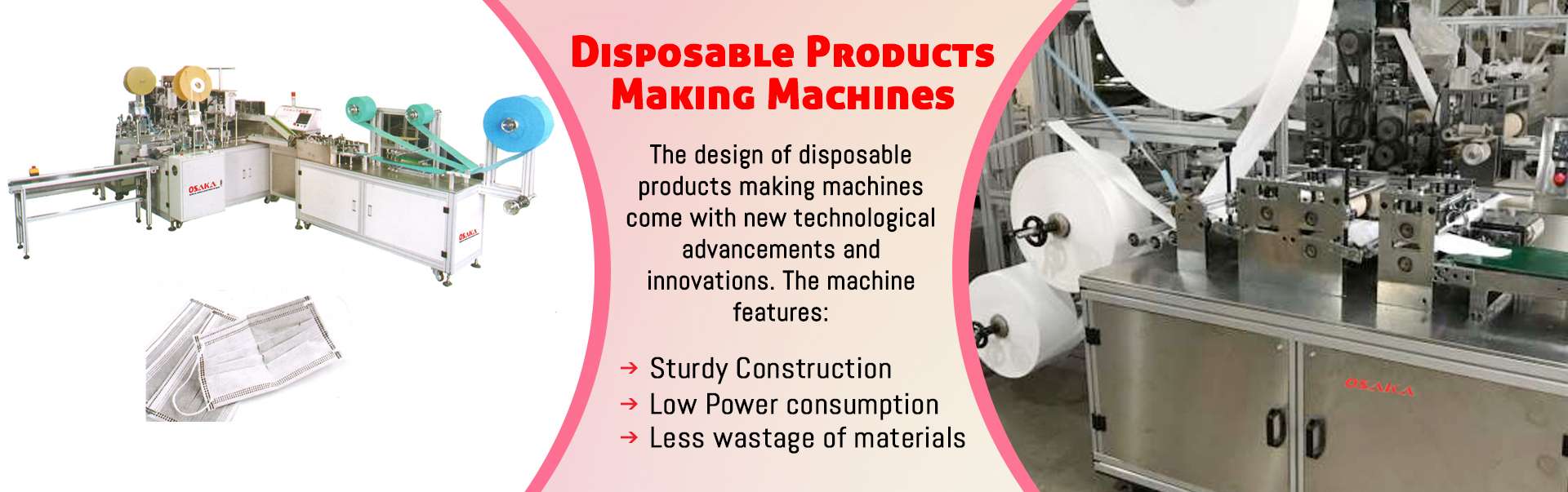

The days are gone when production is accomplished by hand-made products. Many businesses now rely on the machines to get the work done & Why not? This not only saves your time, effort, and money on production but even waste less materials. Our wide range of machines comprises SPM machines, Brick making machines, agricultural machines, disposable products making machines, and many more. With the vast Industrial production, we have counted amongst the Special Purpose Machine Suppliers Exporters Haryana, India. We assist your business in achieving Profitability. Once your business is running well, you will be inclined to let things continue to run as they are.

Supreme Quality

We have a vast infrastructure facility that enables us to produce a specific set of machines in large quantities. By taking into account the recent industrial norms and policies, our machines are produced under the supervision of our professionals. The machines we deliver are tested and inspected on a variety of quality standards. Our manufactured products are widely acclaimed for superior Quality, easy to operate, sturdy construction, superior Performance, and low maintenance is required. That’s the reason why we receive demand from all over India and the world. We are competent enough to meet large demand without compromising on Quality.

Why Choose Us

Featured Products

Latest Blog

How is face mask effective against Coronavirus?

Can face masks be effective in reducing the spread of the COVID-19-causing coronavirus? Ofcourse, yes. Face masks are widely used as other preventive ...

Read MoreHow Power weeders aid in Farming?

A power weeder is a piece of farm machinery used for secondary tillage. Another word for teeth is shanks, which penetrate the soil by being dragged st...

Read MoreWhat should you opt for: Handmade bricks or Machine Made bricks?

It's challenging enough to choose clay facing bricks as it is. It can take a long time to narrow down brick colours, textures, designs, and measur...

Read MoreThanks to the baby diaper Making machine which I purchased from Osaka International last year. The machine offers superior functionalities as it enables us to meet even bulk demand within a shortest amount of time. I truly appreciate Osaka International for such advanced machinery.

I have purchased a face mask making machine from Osaka International which aids us to meet the growing demand for face masks. Processing is very fast and the pricing is also reasonable here.

Our comprehensive range includes Manual Sanitary Napkin Making Machine, Automatic Sanitary Pads Making Machine Model No: OS-ND80 Anion chip and Sanitary Pads Making Machine.

The thermal fogger is the polar opposite of the cold fogger. They're also known as ULV (ultra-low volume) foggers since they don't utilise heat to evaporate the fogging liquid, instead opting for the cold spraying approach, which in most cases employs air pressure to spray the liquid out in minute particles.

Pest control firms utilise portable thermal fogging devices outside to eliminate mosquitoes and other outdoor pests. Because they need gas or propane to operate, they are a fire danger and should not be used indoors.

Ash bricks are superior to clay bricks in every way. They are environmentally good because the majority of the constituent is ash, and fly ash bricks are stronger than red bricks. Fly ash brick, which is the best brick for home construction, is an option.